Customised vs Custom Enclosures For Your Industrial Electronics

There are two ways of specifying a custom enclosure for industrial electronics: the expensive way and the smart way. Going fully bespoke can be costly because it means starting with a blank sheet of paper. This is true for virtually any form of electronic enclosure – but especially so for the industrial sector because the cases will probably need to be diecast aluminium. That means higher tooling costs – not the most cost-effective way to go custom.

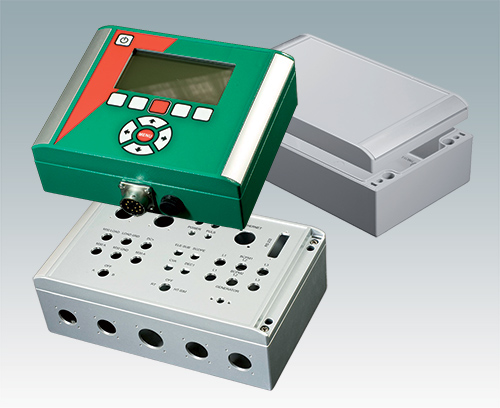

And then there’s the smart way – specifying a standard diecast (or stainless steel or GRP) enclosure and having it customised. Long ago, back in the days before ROLEC, this meant selecting a basic diecast metal box and creating a few apertures for cable glands, switches and connectors. The result was sturdy and functional but unlikely to be mistaken for an objet d’art. But that was then…this is now, and customised industrial enclosures now look smart, modern and fit to grace any modern factory or technical facility that has one eye on production efficiency and the other on industro-architectural chic.

But what if you could have the best of both worlds? What if you could specify a housing to within a millimetre – ie, pretty much bespoke – and yet enjoy all the cost benefits of specifying a customisable standard enclosure? The fast-moving world of Industry 4.0, the Smart Factory and the Internet of Things is making all that possible. Actually, not just more possible…it’s making it more probable…

How HMI/Command Enclosures Are Rewriting The Rulebook

The days of small metal boxes comprising little more than six flat sides and a button are not over…but now the expectations are much higher. Mission control in a 21st century manufacturing plant is infinitely more sophisticated. Today’s modern human-machine interface (HMI) is a large touchscreen attached to a modular suspension arm (or the more cost effective option of a wall pivot mount). The beauty of these enclosures – and they are extremely aesthetically pleasing – is not just skin deep: it lies in their smart design.

Unlike diecast aluminium enclosures or folded and welded stainless steel enclosures, this new generation of IP rated HMI/panel enclosures is manufactured from aluminium profiles. This makes it possible to specify plan sizes to within a millimetre in either axis (up to 800 x 800 mm). Enclosure depth is determined by the width of the profile (or combination of profiles) – making it easier to offer a wide choice of sizes and capacities. From that point it’s simply a matter of choosing your preferred door or handle options. Maximum choice, minimum hassle – it couldn’t be easier, especially when there are standard options designed specifically to accommodate displays by leading manufacturers such as Siemens, Beckhoff and B&R.

Which HMI/Panel Enclosures Are Best For My Electronics?

There’s much more to this type of housing than first meets the eye. Various HMI/panel enclosures can look very similar…and they can be constructed in what initially appears to be the same way (from extruded aluminium profile)…but that is not the full story. There are significant cost savings to be enjoyed by selecting the right model.

A flagship model such as ROLEC’s multiPANEL offers cutting edge aesthetics and a wealth of technical features. There are various front plate and rear panel options (a bolted panel or a choice of rear doors) plus accessories such as keyboard trays and handles. But despite this – and the fact that you can specify any plan size up to 800 x 800 mm – there is another option that may better suit your project. That’s hard to believe when a supposedly standard housing like multiPANEL can be so bespoke and so customisable but it’s true: there is another panel enclosure that offers a wider choice of sizes…profiPANEL. ROLEC multiPANEL and profiPANEL enclosures may look similar. And the design and construction are similar. But profiPANEL has a trick up its sleeve. It combines 90 mm and 60 mm profiles to offer a choice of eight different depths (twice as many as multiPANEL) – and yet with significant cost benefits.

Growing Range Of Customisation Services

Customising a standard enclosure is always faster and more cost effective than going fully bespoke – whether you’re specifying a ‘virtually bespoke’ HMI/panel enclosure or a more conventional diecast aluminium, stainless steel or GRP box. And now that range of customisation options is larger than ever.

CNC machining – milling and drilling – of cutouts, recesses and contours is (or should be) an absolute given, no matter which manufacturer you approach. But does your chosen manufacturer offer all the other customisation services under the same roof as a single-source supplier? Do they have access to the latest technologies or are they more ‘traditional’ in their approach? Do they offer photo-quality digital printing of complex logos, patterns and graduations? Digital printing has superseded the old tampo and screen printing methods – not just because of quality but also because the set-up is much quicker, easier and more cost effective: it helps to make customisation more viable for smaller batches (but remember that a diecast or moulded enclosure will never be as easy to produce in low volumes as a folded metal enclosure because the initial tooling costs will always be higher).

But what if digital printing isn’t enough? What if your IP 69K, IP 67 and IP 66 enclosures have to survive the very toughest environments? What if your products must be bolted to the side of a North Sea oil rig? What if they have to survive repeated high pressure washdowns in an abattoir? You’ll need engraving (which can be filled with any colour) or – if you’ve specified stainless steel enclosures – laser processing. Not all manufacturers have their own in-house laser processing centre…but we do.

Custom colours are crucial if your new product is going to stand apart from its competitors. That means powder coating or wet painting. Powder coating is the more cost effective option for larger volumes because there is less wastage. But for smaller batches you may better off with wet painting because the set-up costs are lower. Either way, you need a manufacturer who keeps a large range of colours always in stock – that way you’ll get a faster turnaround. We can coat or paint your enclosures in any RAL colour you specify – or match to your own bespoke colour. EMC coatings are also available (along with EMC gaskets…or enclosures with built-in protection such as conFORM which needs no conductive gasket thanks to its smart design).

Partner With Specialist Enclosures Manufacturer – Rather Than a General Distributor

Whatever your requirements, you need more than a supplier: you need a specialist enclosures partner – one capable of playing a key role in the design process, preferably early on to help you gain maximum benefit from their expertise. A true partner is one that is able to provide a full outsourcing solution – offering not just a PCB-ready custom enclosure but also installation and assembly, digitally printed foils or membrane keypads.

Get Expert Technical Advice

Need more information?

- Contact the ROLEC sales team for expert technical advice on our enclosures and control arm systems.

- Talk to us about having your enclosures fully customised to your specifications.

- Ask for a sample so you can see how your product will look in its new housing.

Get Expert Technical Advice

Need more information?

- Contact the ROLEC sales team for expert technical advice on our enclosures and control arm systems.

- Talk to us about having your enclosures fully customised to your specifications.

- Ask for a sample so you can see how your product will look in its new housing.