Specifying Customised Industrial Electronic Enclosures

Industrial electronic enclosure design has changed dramatically to meet the demands of IoT/IIoT and smart factories. Today’s visually stunning HMI/panel enclosures are a world away from the housings used by 20th century engineers.

Giant touchscreens in sleek command enclosures are superseding metal boxes with keypads as futuristic robot-intensive factories lead the way with heavily digitised Industry 4.0 manufacturing. One fundamental factor in all this hasn’t changed though: OEM still want enclosures customised to their precise requirements. But the philosophy behind that customisation – and the methods used to make it happen – have evolved significantly…

Customisation In The Last Enclosures Revolution

Until now, customising a standard enclosure has been a process that occurred at the end. Yes, the customer would have known from day one that they wanted a customised enclosure. And they would have told us that at the start.

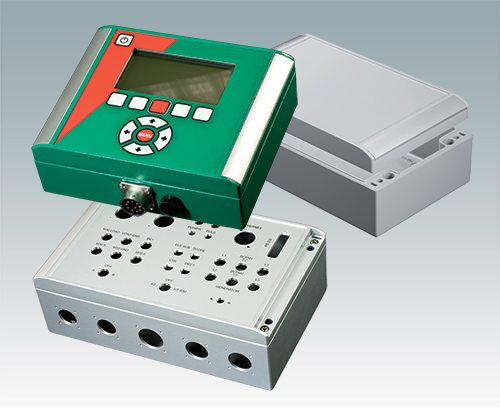

But the actual customisation of a diecast or plastic standard enclosure is carried out on a housing that has already been cast, fabricated or moulded. All the CNC machining, painting/powder coating, engraving, printing and laser processing is performed on an off-the-shelf IP-rated enclosure.

Diecast aluminium housings that can be customised this way include aluCASE (premium enclosures), aluCLIC (with click-fit mounting), aluDISC (for round pipework), aluPLUS (in industry-standard sizes), aluNORM (multivariable, with space-saving single-channel fixings), conFORM (with built-in EMC shielding) and aluTWIN (dual chamber).

All these advanced modern enclosures are IP rated – most of them to IP 66, IP 67 and/or IP 69K – to cope with challenging conditions in heavy industrial, marine and offshore environments. Many offer ‘lid closed’ installation to protect the seals and electronics. Some have clip-on trims to hide the lid screws, further enhancing the aesthetics.

This tried and tested method of specifying a standard enclosure then adding machining and finishing to your order works very well. It’s the reason that customising a standard enclosure will always be quicker, easier and more cost- effective than creating a full bespoke housing from the ground up.

That is especially true when diecasting or moulding are involved because of the high initial tooling costs. Reducing the work involved shortens lead times and enables designers to specify custom(ised) enclosures in much lower volumes.

View Enclosures Range >>

Specifying HMI Enclosures In The Industry 4.0 Age

What if you were to rethink the enclosure manufacturing journey? What if you put customisation at the very start of the manufacturing process? What if you made customisation the essential first step?

So we did – that’s how we can manufacture HMI/panel enclosures such as profiPANEL (up to IP 65) and multiPANEL (IP 65) to your exact specifications so swiftly. Officially, they are standard enclosures…but it’s odd to think of them as ‘standard’ when your first move will be to specify their dimensions to within a millimetre (right up to 800 x 800 mm).

In the case of multiPANEL, you can also choose which front plate variation you would prefer – and whether you would like a bolted rear wall, a bolted door, 15 mm framed door or 60 mm framed door. And dedicated versions are available for Siemens, Beckhoff and B&R displays.

So how are we able to offer ‘customisation as standard’? It’s all in the design: the construction of multiPANEL and profiPANEL is based on aluminium profiles, making sizing easy. Versatile profiPANEL combines 60 mm and 90 mm profiles to offer eight different depths from 60 mm to 300 mm.

Take a long and detailed look at profiPANEL and you’ll see that it offers much more than just a great range of sizes. Options and accessories include a separate desktop keyboard housing, keyboard and mouse trays, handles and mounting brackets. But despite all its versatility, profiPANEL is actually the more cost-effective choice – proving that getting more can cost you less.

View HMI/Display Enclosures Range >>

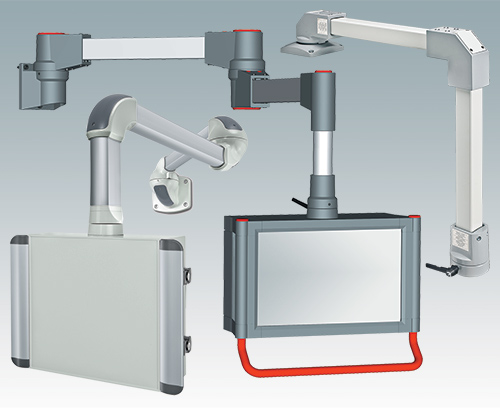

Mounting Your Customised HMI Enclosures

Most HMI enclosures will be mounted on suspension arms (though hinged wall brackets are an option for those on a tighter budgets). And if you are customizing your HMI enclosure at the start of the manufacturing process, then it seems only logical to do likewise with its mounting. After all, modular suspension arms are – by definition – supremely customizable.

Enclosures such as multiPANEL and profiPANEL are designed to be mounted on profiPLUS suspension arms: the 50 model for light loads, the 70 for heavier loads. Both feature patented ‘one screw adjustment’ to speed up installations. Users specify their perfect suspension arm from a wide selection of aluminium couplings and support profiles (in standard or in custom ‘to the millimetre’ lengths). A 70/50 adapter enables you to combine the two ranges.

View suspension arms range >>