Safeguard Your Electronics In Hazardous Industrial Environments

Industrial hazards don’t play fair. They seldom threaten your electronics one by one. They attack in force. They gang up on you. So your electronic devices may have to survive multiple assaults simultaneously – heavy impact, high (or low) temperatures, water and dust ingress, chemicals.

That can make specifying enclosures a real challenge because to guarantee strength in one area, you may have to compromise in another. And that’s a serious issue. Compromise may not be an option – especially where the great outdoors is concerned. So where do you start?

Diecast rather than fabricated aluminium is usually your best starting point when considering industrial electronic enclosures (though it may not be your final choice). It’s strong, light and easy to cast or machine – and therefore quick and cost-effective to customise.

Specify Enclosures Which Offer A Choice Of IP Ratings

You’ll need an enclosure with a high IP rating for superior ingress protection. That much is obvious. But there are significant differences between the three key IP ratings for enclosures of this type:

- IP 66 offers protection against temporary flooding in environments such as heavy seas. Test: Water sprayed against the enclosure from a powerful jet (under elevated pressure and from any direction) will have no harmful effects. (75 litres per minute at 1,000 kPa at a distance of three metres for at least three minutes.)

- IP 67 is required if the enclosure will be fully immersed. Water must not seep into the enclosure in any quantity that could cause damage when the enclosure is submerged underwater temporarily. Test: immersion in water for 30 minutes to a depth of one metre (at the lowest point of the enclosure) or with the highest point 150 mm below the surface, whichever is deeper.

- IP 69K protects against close-range high-pressure water jets and high-temperature spray downs. Test: 14-16 litres of water (at 80°C) is sprayed at 8-10 MPa at a distance of 0.1-0.15 metres for 30 seconds at each of four angles (two minutes in total).

It’s wise to choose an enclosure which offers a range of IP seals. That way you’ll have the option of later upgrading to seals with a higher rating if the working environment becomes more hazardous than first predicted.

Another key feature is ‘lid closed’ installation – separate channels for the lid screws and fixing screws. There’s no point specifying an IP 69K seal if you have to open the lid while you’re trying to install an enclosure in bad weather.

Accessing Your Electronics For Inspection And Maintenance

Re-opening an enclosure for regular inspection and maintenance raises a number of concerns:

- How easy is it to remove the lid? How long will it take?

- How quickly can the lid be replaced if conditions change suddenly?

- What if the enclosure is in a hazardous or bad-weather location?

- Will repeated opening and closing of the lid damage the ingress protection seal or a fragile EMC gasket?

ROLEC enclosures provide answers to all these questions. It’s simply a matter of specifying the most suitable model for your specialised requirements and for the intended operational environment…

How Easily Can The Enclosures Be Installed?

Pretty fast if you specify our new aluDOOR (IP 66/67/69K) industrial electronic enclosures. These ‘compact cabinets’ feature a hinged lid that can be locked tight or reopened with just two screws. And the recessed/unrecessed lid opens 100° for easier access.

Like the premium aluCASE (IP 66/67/69K) on which it’s based, new aluDOOR features separate fixing screw and mounting screw channels for ‘lid-closed’ installation. But aluDOOR’s smart hinge design is more advanced than the optional hinges offered on aluCASE. The aluDOOR hinge design features A2 stainless steel lid screws and threaded inserts to ensure a corrosion-resistant assembly in extreme conditions.

Fitting aluDOOR’s lid is quick and easy. The lid with integrated hinge pin is pushed into place then secured with two tamperproof Torx T25 (M5) screws. Then the lid is shut and locked down with two more T25 screws. Extruded aluminium trims conceal and protect the lid screws and mounting screws (just like on aluCASE).

Will Repeated Opening And Closing Of The Lid Damage The Ingress Protection Seal Or EMC Gasket?

When it comes to ingress protection, any enclosure is only as good as its seal. And in turn, that seal can also have a weak point. Most IP seals feature a join – a potential vulnerability. But that is changing. Increasing numbers of ROLEC enclosures (including new aluDOOR) are now being fitted with new foamed-in IP seals that have no join: the seals are continuous, providing the reassurance of long-lasting protection.

Great – but what about the EMC gaskets? Anyone who’s ever handled these delicate lattice-works will tell you how notoriously fragile they are. Repeated opening and closing of enclosures puts these gaskets at risk, jeopardising the electrical continuity needed to ensure the integrity of the Faraday cage used to stop electromagnetic interference.

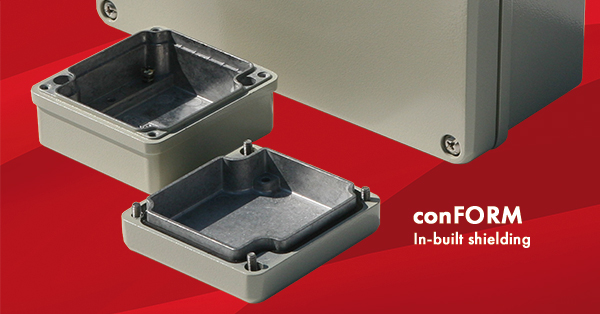

ROLEC’s answer is to offer two enclosure models that get rid of EMC gaskets altogether: our innovative conFORM range and deeply recessed conTROL enclosures both feature built-in EMC shielding thanks to a patented tooth system pre-cast into the lid and base. The teeth interlock, creating the connection needed to ensure continuity – over and over again, a great connection every time. You’ll be glad you specified this feature, especially when enclosures have to opened in challenging outdoor locations.

But there are other questions that can trouble the designers of industrial electronics…

What If My Enclosures Need Enhanced Protection Against Chemicals?

Glass-reinforced polyester (GRP) is robust, versatile and highly resistant to chemicals – and it is also cost-effective. ROLEC’s GRP enclosures are used in oil and petrochemical facilities all over the world:

- polyTOP (IP 66/67) features single-channel fastening to maximise interior space – and a choice of polyamide lid screws (hex-key, triangular, slotted).

- polyKOM (IP 65) is manufactured in industry-standard sizes, making them interchangeable with other standard products. Options include external hinges, supporting hinges and mounting brackets.

- polyDOOR (IP 66) offers a hinged front lid, optional lid window and a choice of lid screws – slotted (standard), triangular or square (to deter tampering) and hand screws (for easy access).

Specify Customised Industrial Electronic Enclosures

Every standard enclosure needs some form of customisation, even if it’s merely machining a few apertures for cable glands and/or other connectors. And a single-source supplier like ROLEC can also carry out all the other customisation work so your enclosures arrive ready for your electronics. You can send them straight from Goods In to your production line for installation of components.

You would be surprised how little customisation is needed to colour-brand an enclosure. Sometimes just specifying different coloured trims may be enough. And in some cases, you may be able to do that as standard.

ROLEC’s customisation options include CNC machining; laser processing; engraving; photo-quality printing of legends, logos and graphics; display windows and assembly. Find out more here about our full range of customisation services

View ROLEC's full range of tough enclosures >>Further Reading

- Which Metal Handheld Enclosure For My Industrial Electronics? Read more…

- Six Key Questions To Ask When Specifying Diecast Electronic Enclosures. Read more…

- Specifying Customised Industrial Electronic Enclosures. Read more…

- How Best To Colour-Code Or Brand Your Industrial Electronic Enclosures. Read more…

Get Expert Technical Advice

Partner with specialist enclosures manufacturer ROLEC early in your design process and you’ll benefit from expert advice that could save you vital time and money. Our decades of experience will help you to specify the best enclosures (and customisation options) for your electronics.

Contact us now so we can discuss your requirements.